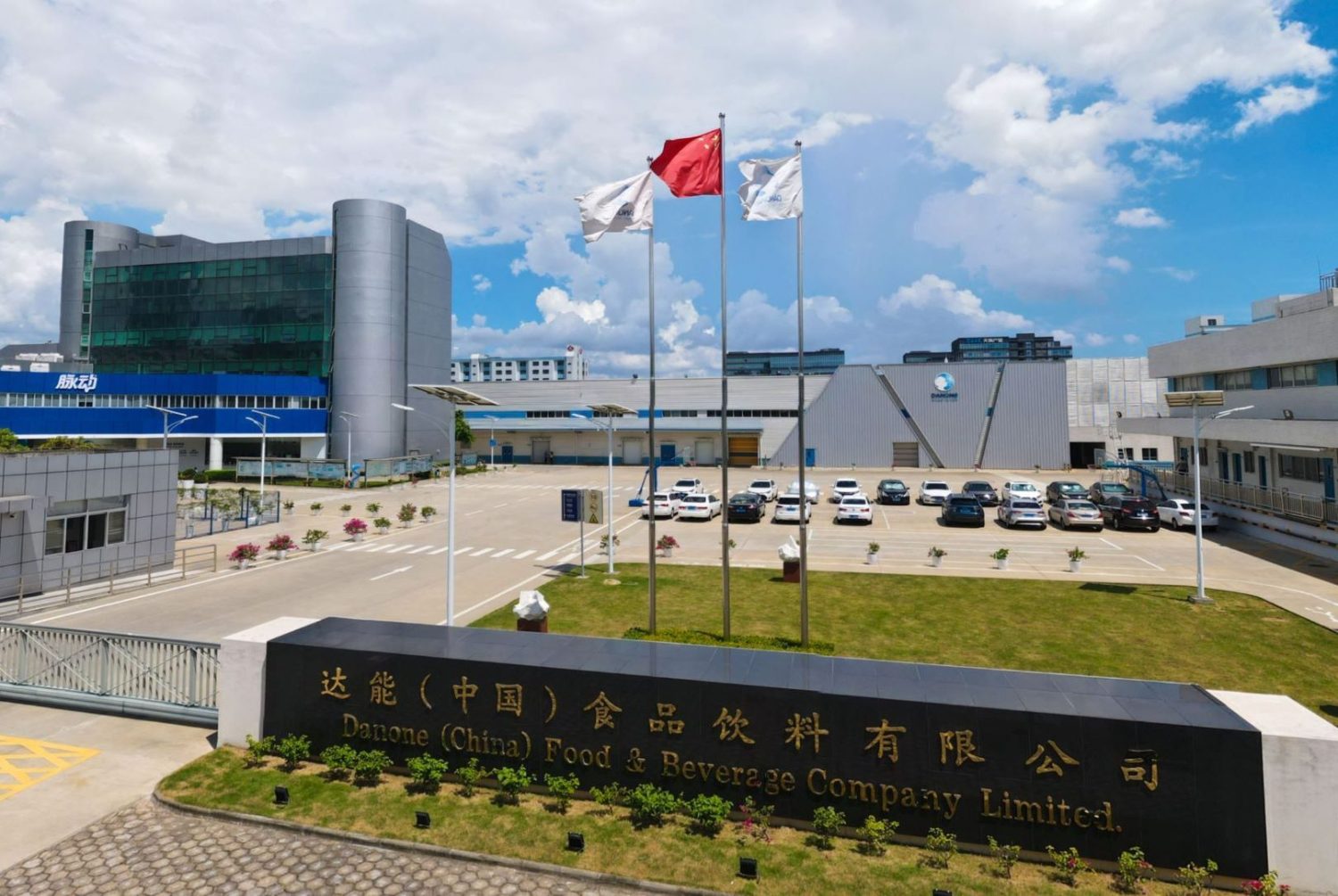

Danone (China) Food and Beverages Co Ltd transitioned from ISO 22000 to FSSC 22000. Mr. Dai, Associate Director of Food Safety and System of Danone (China) will share his experiences during this transition.

This article is also available in the following languages:

With over 5000 employees, 25 local sales offices, six factories, and headquarters in Guangzhou, Danone China Food and Beverage is a big player in the market of vitamin drinks. Mr. Dai, Danone’s Associate Director of Food Safety and System of more than nine years, will tell us more about this transition.

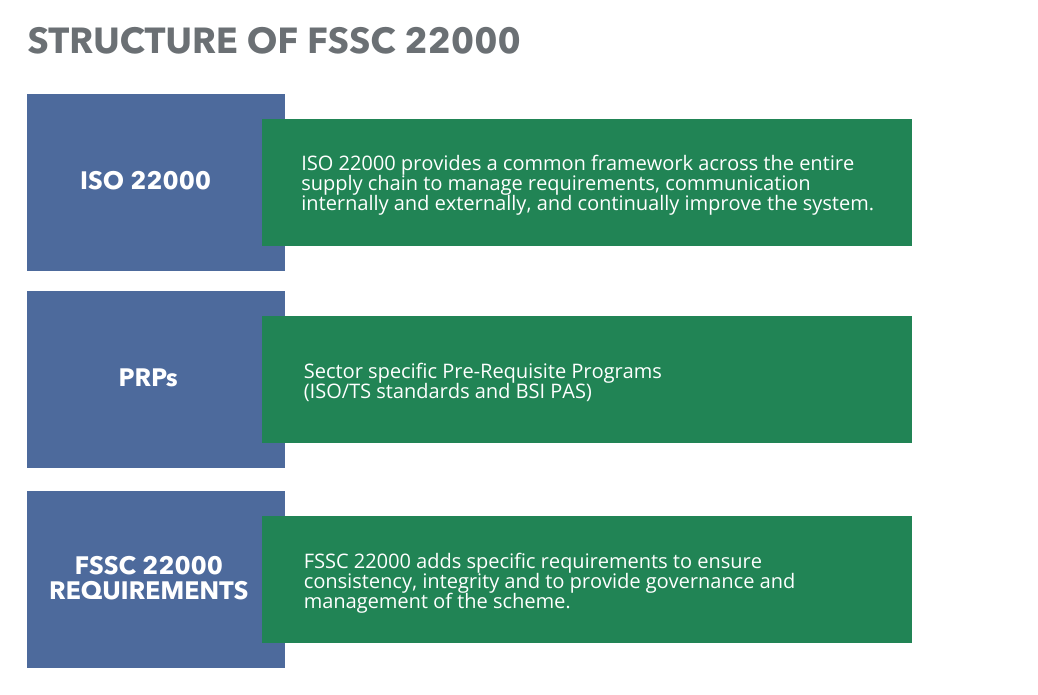

From ISO 22000 to FSSC 22000

All of Danone’s factories had been ISO 9001 certified already when in 2010, it was also decided to become ISO 22000 certified. ISO 22000 has the same management system structure as ISO 9001 and focuses only on food safety, while ISO 9001 covers quality management and applies to multiple industries. This focus was one of the primary reasons for Danone to implement the ISO 22000 standard. But it didn’t stop there.

In 2014 the Danone’s global headquarters required the transition of ISO 22000 to FSSC 22000 certification from all of their sites. This requirement resulted in the first of the six beverage factories in China becoming FSSC 22000 certified in 2014, while the other followed in the years coming. The last site received certification in 2016.

- How did the transition process start?

“We didn’t experience the transition as challenging, and it ran very smoothly. It all started with training on the pre-requisite programs (PRPs) and additional requirements necessary for FSSC 22000 certification. When the training was over, we reviewed the PRPs and additional requirements one by one to enhance our existing food safety management system. After six to nine months, we were ready for our first FSSC 22000 audit, and we only received one non-conformity. The reason for this smooth transition is that we had a strong ISO 22000 foundation in place. Because of that, we could focus on all of the additional requirements and sector-specific pre-requisite programs and build upon the food safety system we had in place.”

- Did you experience benefits from the FSSC 22000 certification?

“What we experienced is that the pre-requisite programs and the FSSC 22000 additional requirements are more specific to our sector and, most of all, more systematic. Implementing the PRPs helps prevent specific food safety issues from happening, like cross-contamination.

Another significant benefit was the FSSC 22000 additional requirements like the unannounced audits. For our China sites, we have introduced unannounced audits as the standard. So every year, we are audited unannounced instead of announced by our Certification Body. But this doesn’t only apply to our third-party audits. For our internal audits, we have implemented a similar system of unannounced audits.”

Thank you for sharing Danone’s transition story with us, Mr. Dai. Do you have a few final words for other ISO 22000 certified organizations regarding this transition?

“Our experience with FSSC 22000 is that it is a good and systematic scheme. We notice that more and more clients recognize it, and it contains specific and clear requirements. Having ISO 22000 in place made as our foundation it easy to move to FSSC 22000 certification. And the transition brought us the benefit of improving our internal food safety procedures by using the additional requirements of the robust food safety management system FSSC 22000.”

Explore our insights

-

FSSC Summit India 2025

Hyatt Regency Hotel, Chennai, India

|

25 April, 2025

-

Insights Webinar FSSC 22000 - One Year of Version 6: Top Nonconformities and Guidance

Past event

|

25 March, 2025

-

FSSC Insights Webinar | FSSC 24000: Supporting CSDDD Social & Governance Challenges

Past event

|

12 February, 2025