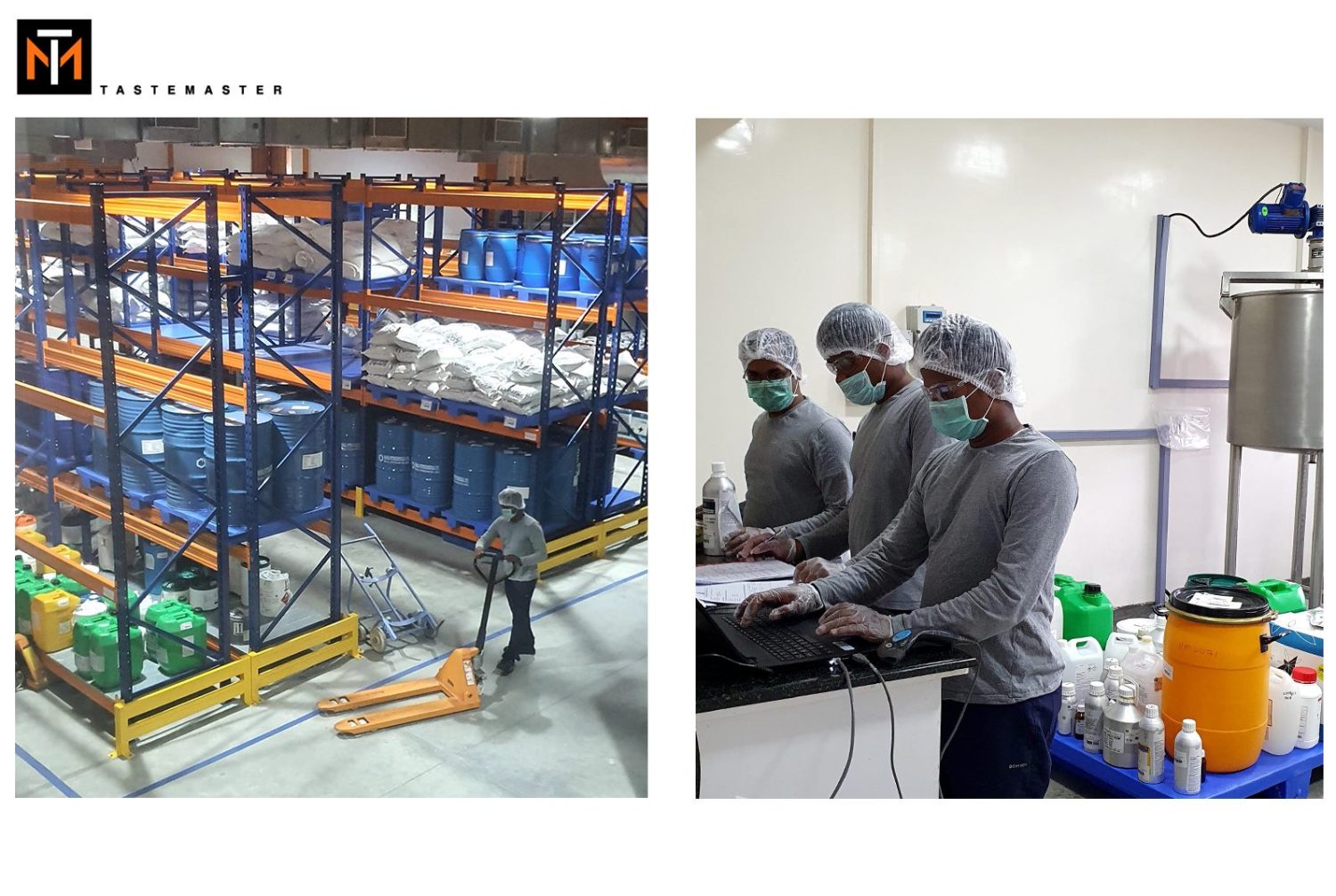

‘Taste Master Flavours’ is an India-based manufacturer of a wide range of quality flavors for food, beverage, pharma, and nutraceutical industries, pan-India and abroad. Certification is an essential element in the growth strategy of Taste Masters, and in this article, they will share their certification journey.

The decision for FSSC 22000 certification

“Our goal was to have an externally audited process to guide the team to follow the best practices in line with international standards, and FSSC 22000, being a GFSI compliant Scheme, had that edge. Domestic customers who came to audit us expected a minimum of ISO 22000. but we wanted not just to meet but exceed their expectation when it came to the quality and safety of our products. Being certified against a global standard would also take the issue of quality and safety out of the way while talking to our international customers to support our growth goals. All these tipped the scale in favor of FSSC 22000 compared to ISO 22000.

In choosing which scheme would work best for our company, we found it invaluable to gain external advice from a consultant that understood our motivations and provided the right inputs to help with the decision making. We recommend getting this advice as early as possible in the process.”

Taste Master’s advice in the decision-making process:

- A gap audit by the Certification Body was helpful. This way, we learned about the gaps between the (back then) current level of food safety and the desired level of food safety. This gap analysis also helped get a cost indication of the upgrade necessary to comply with the new standards.

- Choose a Certification Body with good credibility in the market and thoroughness to ensure the standard is implemented correctly.

- The changes must make sense for your organization – don’t think about getting certified just for obtaining a certificate – it is not worth the effort.

- Certification is a critical tool for reducing dependency on individuals and improving and creating a process-driven work culture. At Taste Master, we value our people over tools and processes, but a robust and practical approach is required to guide the team.

How did implementing FSSC 22000 help Taste Master?

The primary motivation for Taste Master to select a Scheme was two-sided. On the one hand, we wanted to drive our people and processes to higher performance. And on the other hand, create a good position for our company in our growth ambitions.

FSSC 22000 forces you to analyze many potential risk-factors companies don’t usually consider and develop strategies to mitigate such risks. E.g., one of the components is to examine the ‘Needs & Expectations’ of all interested parties, including all suppliers & vendors you depend on, your employees, etc. This analysis is a useful exercise to mitigate potential risks and supported us in becoming more proactive in reducing food safety-related risks.

The implementation has driven the entire organization to think and act 'food safety.'

Apart from Food Safety, there have also been HR benefits from implementing FSSC 22000 and being independently certified, which include:

- Career Development of our team by keeping them up to date with the highest industry standards.

- Less dependence on individuals because so much learning and experience goes into the Standard Operating Procedures (SOPs).

- Standardizing processes makes onboarding new employees easier.

- Implementing FSSC 22000 helped overcome internal resistance to food safety requirements such as no jewelry or mobiles in the production area.

- It helps us define business objectives that support food safety and ensure that we track and monitor achievements.

Finally, our FSSC 22000 certification helps in marketing our products because it is a globally recognized Scheme and the well-established Certification Body that audited us. This provides confidence to our customers trust Taste Master with critical flavor requirements and more extensive briefs, which means sales growth!

The challenges of implementing FSSC 22000

We have experienced a few challenges while implementing FSSC 22000. But as they say: “no pain, no gain!”.

- Documentation increases. We have had to increase resources in some areas to manage the growth in documentation, but there are upsides. All our approved process documents are now stored online, which has made it easier to handle during the COVID pandemic, with some managers working from home.

- Bringing all production staff up to speed with the new standards requires frequent training in addition to the FoSTac training we already provide.

- We needed an external consultant to guide the process. That is essential for any small to medium company planning on certification.

- The upgrade process required a significant investment of time from several staff members across various teams, who had to multi-task to cover the requirements. Fortunately, our Technical Manager was able to Project Manage the process. It is essential to have someone internally who is passionate to drive the process as there will be a significant amount of extra effort and teamwork required.

- Our QC manager and Supply chain Manager led the FSTL team. While preparing for the audit, many resources had to put in significant time and energy to upgrade the process and systems, which had to be maintained and followed.

- Taster Master also had to make various upgrades to infrastructure as recommended by the consultant and auditors, all of which cost money. However, in all cases, they made sense for the company in the long run anyway. Many of the investments and changes we made for FSSC 22000 compliance prepared the company for the challenges during the COVID pandemic. For example, implementing a robust software system makes batch traceability easy. Next, it facilitated the implementation of most process requirements online with ease, rather than being overloaded with paperwork.

The implementation of FSSC 22000 had strong buy-in, support, and drive from the top, especially from our MD and Technical Manager. This drive is fundamental to minimize pain points in implementing a new Scheme. In the end, we must say that it has been entirely worth the journey for the organization, and we have emerged a lot more mature in the process.

About Taste Masters

Taste Masters helps manufacturers deliver good taste appeal and consistency in a wide range of consumer products, all of which require guaranteed quality and food safety. Taste Masters has always gotten a strong focus on systems, quality, safety, sustainability, and a strong sense of responsibility for the safety of the company employees, products, customers, and end consumers. The company started in 2002, and its certification journey was driven mainly by the ever-improving quality and food safety standards demanded by many of our corporate customers.

Before building our company-owned manufacturing facility, Taste Master manufactured its flavors in a rented facility. Many customer audits were conducted in that facility, and we achieved our first quality certification under IS09001:2008 + HACCP. At the time, adopting these standards certainly helped our organization achieve sustained growth, with near-zero product issues. Also, the learnings from these audits were invaluable when planning and constructing our manufacturing facility to be compliant with world-class food safety and quality standards.

Explore our insights

-

FSSC Summit India 2025

Hyatt Regency Hotel, Chennai, India

|

25 April, 2025

-

Insights Webinar FSSC 22000 - One Year of Version 6: Top Nonconformities and Guidance

Past event

|

25 March, 2025

-

FSSC Insights Webinar | FSSC 24000: Supporting CSDDD Social & Governance Challenges

Past event

|

12 February, 2025