Prioritizing food safety along the supply chain is crucial. Organizations can achieve this by implementing a robust and resilient food safety management system (FSMS) like FSSC 22000. FSSC 22000 follows a risk-based approach, incorporating ISO 22000 standards and emphasizing proactive risk identification and control.

When food is not safe, people cannot consume the nutrients they need to stay healthy, to learn and study, or to go to work. More than 600 million people fall ill, and 420,000 die every year after eating contaminated food. These illnesses and deaths are largely preventable if we prioritize food safety along the food supply chain, from the producer to the consumer.

To effectively manage food safety, preparedness is key. When the unexpected happens and food safety is compromised, strong and resilient food safety management plans are essential to stay ahead of food safety incidents and protect the consumer.

One effective way for organizations to do this is by having a robust and resilient food safety management system (FSMS) like FSSC 22000 in place.

Food Safety Management with FSSC 22000: A Risk-based Approach

FSSC 22000 is a risk-based FSMS that provides effective management for controlling food safety hazards, minimizing risks, and enhancing the production of safe food. The international food safety standard ISO 22000 is incorporated in FSSC 22000 and follows a risk-based management approach. Integral to this approach is a Plan-Do-Check-Act (PDCA) cycle and risk-based thinking that enable an organization to ensure its processes are adequately resourced and managed and that improvement opportunities are identified and acted upon in a timely manner.

The FSSC 22000 Additional Requirements and sector-specific pre-requisite requirements amplify this approach and allow to specifically tailor the certification Scheme to different food chain categories. These include food manufacturing, transport and storage, retail, wholesale and e-commerce, and catering and food services, as well as the production and manufacturing of animal feed and packaging materials.

Whether it is a power outage at a factory, food poisoning at a local restaurant, a manufacturer’s voluntary recall of contaminated products, or an outbreak from imported products, food safety incidents can range from minor events to major international crisis and affect all categories along the food supply chain.

FSSC 22000 applies a strategic approach to proactively identify, manage and control food safety incidents in all certified food chain categories, using risk-based thinking and the Plan-Do-Check-Act (PDCA) cycle.

Risk-Based Thinking as part of FSSC 22000

Risk-based thinking involves anticipating potential risks to make informed decisions and take proactive measures to mitigate those risks. In food safety management, risk-based thinking ensures that organizations identify, evaluate, and prioritize risks that could affect food safety.

When identifying risks, organizations should anticipate potential hazards, threats or vulnerabilities in their operations that could lead to food safety issues in the supply chain. The FSSC 22000 Additional Requirement on Food Defense, for instance, mandates organizations in all food chain categories to conduct and document a food defense threat assessment to identify and evaluate potential threats linked to the processes and products within the organization; and develop and implement appropriate mitigation measures for significant threats to prevent or reduce their impact on food safety.

Food Safety Threats and Risks Vary per Food Chain Operation

While FSSC 22000 requires organizations in all food chain categories to practice risk-based thinking, the type of risks and threats varies according to specific food chain operations.

Organizations that produce and manufacture food packaging, for instance, need to consider threats that are inherent to the packaging materials and their potential harm to product safety. Inappropriate or unsanitary packaging components may result in the contamination of the packaged product ranging from toxins, chemical migration, or even breakages from the use of fragile glass or hard plastics.

To control and mitigate risks, the FSSC 22000 Additional Requirement on Hazard Control and Measures for Preventing Cross-Contamination requires organizations to have controls in place for foreign matter management. These shall include procedures for the management of all breakages linked to potential physical contamination, such as metal, ceramic, or hard plastic.

Furthermore, organizations involved in the transportation and storage of food, feed, and packaging, are responsible for safe transportation and storage procedures that protect their cargo, such as raw materials, processed and packaged foods, and packaging products, from hazards, contamination, and adulteration. For example, companies that use tankers for transporting their final products shall have a risk-based plan to address transport tank cleaning, consider potential sources of cross-contamination, and develop appropriate control measures that validate the cleanliness of the tanker, as mandated as part of the FSSC 22000 Additional Requirement on Transport, Storage and Warehousing.

In an increasingly interconnected global food supply chain, providing safe food is a collective responsibility and requires a coordinated approach across the food industry to protect the consumer. Safe transport and storage of food, feed, and packaging are important for growers, manufacturers, retailers, and food service organizations alike. All rely on an intricate distribution network to ensure that products arrive safely and in good condition at their destination.

By integrating a risk-based FSMS into their operations, organizations are prepared for food safety incidents before they occur and are equipped to mitigate their adverse effects on food safety when they occur. This contributes to a more reliable supply of safe food, protects the consumer, and delivers trust and impact to the consumer goods industry.

Continuous Improvement with the PDCA Model

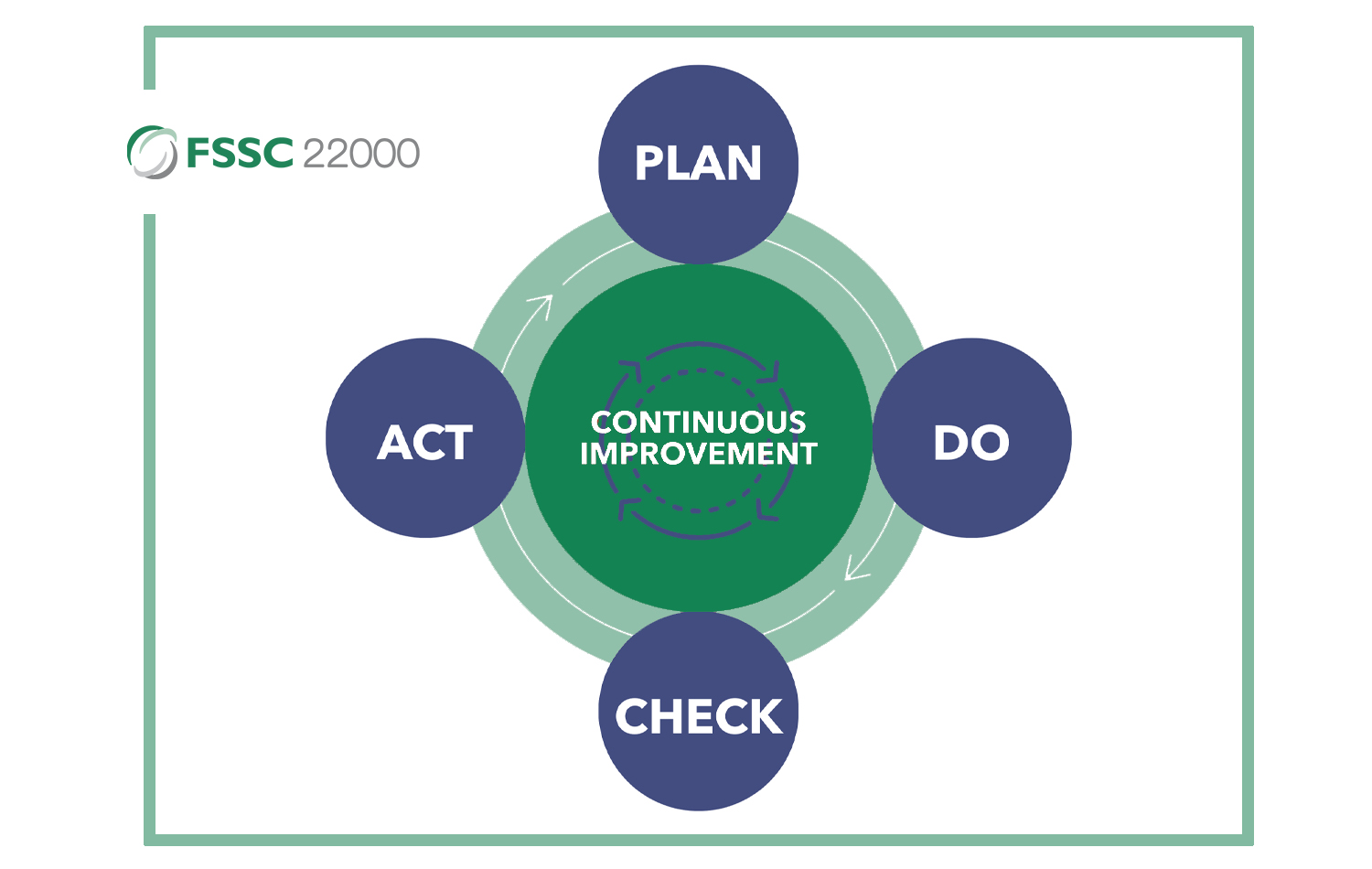

To continuously improve the implementation of the Scheme requirements, FSSC 22000 integrates the Plan-Do-Check-Act (PDCA) model in all food chain categories as a fundamental component of the ISO management system approach.

The PDCA model allows an organization to determine the factors that could cause its processes and food safety management system to deviate from the planned results, put preventive controls in place, minimize adverse effects, and maximize opportunities as they arise. The model follows a four-step cycle:

Plan: Identify and analyze the problem or opportunity, set objectives, and develop a plan to achieve the desired outcome. This step involves understanding the current situation, defining the scope, and determining the necessary resources and actions.

Do: Implement the plan. This phase involves executing the planned actions, training staff, and collecting data on the process and outcomes.

Check: Monitor and evaluate the results of the implementation against the expected outcomes. This step involves analyzing data, reviewing performance, and identifying any deviations from the plan.

Act: Based on the results of the Check phase, take action to improve the process. If the plan was successful, it can be standardized and implemented. If there were issues, adjustments are made to address them, and the cycle begins again with a new Plan phase.

The PDCA cycle promotes continuous improvement by ensuring that processes are regularly reviewed and enhanced, leading to better performance and higher food safety standards.

When the Unexpected Happens, Preparedness is Key

There are exceptional situations in which, even if we have all played our part, unexpected risks intervene, and food safety is compromised. In this case, timely, transparent, and accurate information sharing among all relevant partners helps identify the nature and origin of food safety events and saves lives. The Additional Communication Requirements in the FSSC 22000 Scheme address mandatory notification of serious events and situations to the Certification Body and require organizations to implement suitable emergency preparedness and response processes. This helps maintain a transparent food supply and can prevent further illness.

Integrating the FSSC 22000 FSMS into business operations prepares Certified Organizations to proactively identify and effectively mitigate potential food safety risks. It further promotes continuous improvement by ensuring that processes are regularly reviewed and enhanced. This leads to better performance and higher food safety standards.

The benefit of tailoring FSSC 22000 to specific food chain categories with the technical specifications for sector-specific pre-requisite programs allows for a comprehensive food safety approach across the supply chain. This underscores the shared responsibility of food safety – from the producer to the consumer – and supports the universal principle of WFSD: Food safety is everyone’s business.

Explore our insights

-

Insights Webinar FSSC 22000 - One Year of Version 6: Top Nonconformities and Guidance

Online

|

25 March, 2025

-

FSSC Insights Webinar | FSSC 24000: Supporting CSDDD Social & Governance Challenges

Past event

|

12 February, 2025

-

FSSC Insights Webinar | FSSC 22000: Protecting Food, Reducing Waste with Smart Packaging

Past event

|

4 December, 2024